-

Filter Reactor (Nutsche Filter)

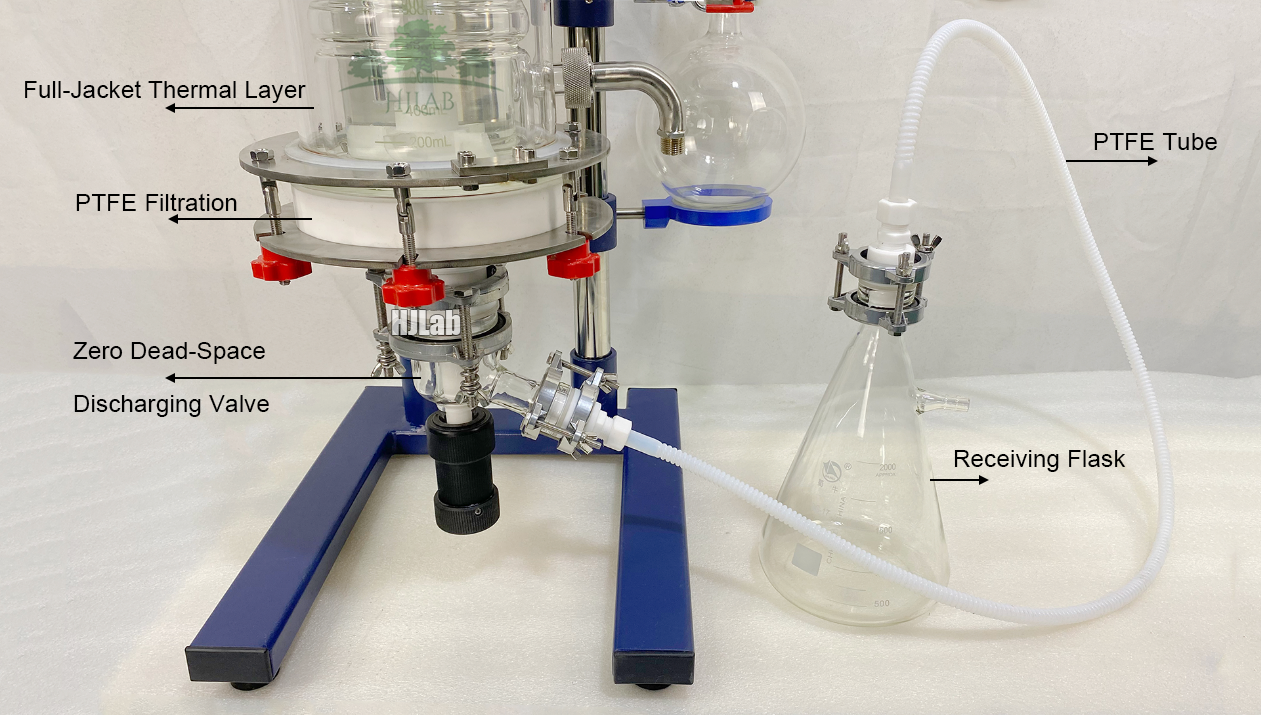

HJLab Benchtop Filter Reactor is a compact system that integrates the functionality of a reactor and a filter in one system at a benchtop scale. The result is a seamless workflow for crystallisation processes. Our Benchtop Filter Reactor performs synthesis of crystalline products and subsequent filtration/washing cycles and its full jacket design allows reactions to happen efficiently due to excellent thermal transfer.

Filtration is assisted by either vacuum or gravity, and the resulting product cake can be dried under vacuum. A quickly removable filtration part makes it easy to collect wet product cake or dried powder, change the filter cloth, and clean the filter. The filter membrane/cloth can be chosen based on your process need.

-

- Reaction, filtration and washing in one vessel

-

- Contamination-free material processing

-

- Vessel swing/rotating mechanism for easy product collection

-

PTFE Filtration Module

-

PTFE Filtration Module

|

Items |

Details |

|

Glass Materials |

High Borosilicate Glass 3.3 |

|

Wetted Parts |

Glass and PTFE |

|

Reaction Vessel Capacity |

500ml, 1000ml, 2000ml, 3000ml, 5000ml |

|

Thermal Jacket |

Full Jacket Design Optional (Ring Baffles within the Thermal Jacket) |

|

Vacuum Jacket |

Optional (Triple Layers Glass Vessel) |

|

Filtration Area |

78 cm² (500ml, 1000ml) 113 cm² (2000ml) 176 cm² (3000ml, 5000ml) |

|

Filtration Micron |

Micron: 0.2μm to 200μm (depends on your materials) Filtration Materials: PTFE membrane or PTFE fabric or Glass Disc Note: Not included by default |

|

Stirring Motor |

DC Brushless Motor, 50W, 100W, 150W AC Motor with Gear Reducer: 120W, 250W Explosion-Proof Motor: 180W, 250W Stirring Range: 50 ~ 2000 RPM Realtime Display: Mixing Speed, Materials Temperature, Torque |

|

Mixing Sealing |

Standard: HJLab PTFE + Ceramic bearing

Optional: Germany PTFE sealing kits |

|

Condenser |

Cooling Coil Condenser |

|

Dropping Feeding Funnel |

Dropping Feeding Funnel with PTFE Metering Valve and Equalizing Arm |

|

Glass Lid |

5 Openings: 1) Dropping Feeding Funnel 2) Stirrer 3) Temperature Probe 4) Condenser Reflux 5) Reserved (By default: Pressure Release) |

|

Stirring Impeller |

PTFE Anchor Type PTFE Pitched Paddle Type PTFE Frame Type |

|

Operating Temperature |

-90℃ to +230℃ |

|

Operating Pressure |

Full Vacuum to Atmospheric Pressure |

|

Operating Jacket Pressure |

Up to +0.5 bar (0.05 MPa) |

|

Power Supply |

100V ~ 240V, 50Hz/60Hz |

-

Turnkey Package